Is Cu-Zn alloy a metal or nonmetal? This intriguing question delves into the fundamental nature of this material, unraveling its properties and characteristics to reveal its true classification. Join us on an enlightening journey as we explore the defining traits of metals and nonmetals, examining Cu-Zn alloy’s electrical conductivity, luster, malleability, and more, to uncover its true identity.

Introduction

Cu-Zn alloy, also known as brass, is a metallic alloy composed primarily of copper (Cu) and zinc (Zn). Understanding whether Cu-Zn alloy is a metal or a nonmetal is crucial because it determines its fundamental properties and potential applications.

Metals are generally characterized by their high electrical and thermal conductivity, luster, malleability, and ductility. Nonmetals, on the other hand, exhibit contrasting properties, such as low electrical and thermal conductivity, dullness, and brittleness.

Properties of Metals and Nonmetals: Is Cu-zn Alloy A Metal Or Nonmetal

Metals and nonmetals possess distinct characteristics that define their physical and chemical properties. Understanding these properties is crucial for comprehending the behavior and applications of various elements.

Key Characteristics of Metals

Metals are renowned for their exceptional electrical and thermal conductivity, allowing them to transmit heat and electricity efficiently. Their lustrous surfaces reflect light, giving them a characteristic shine. Additionally, metals exhibit malleability, the ability to be hammered or rolled into thin sheets, and ductility, the capacity to be drawn into wires.

Defining Features of Nonmetals

Nonmetals, in contrast, are poor conductors of electricity and heat. Their surfaces lack luster, appearing dull or opaque. Nonmetals tend to be brittle, meaning they break easily when subjected to force. They also have low densities and are often gaseous or liquid at room temperature.

Composition and Structure of Cu-Zn Alloy

Cu-Zn alloy, also known as brass, is a combination of copper (Cu) and zinc (Zn). The composition of brass can vary, with different proportions of copper and zinc resulting in alloys with distinct properties.

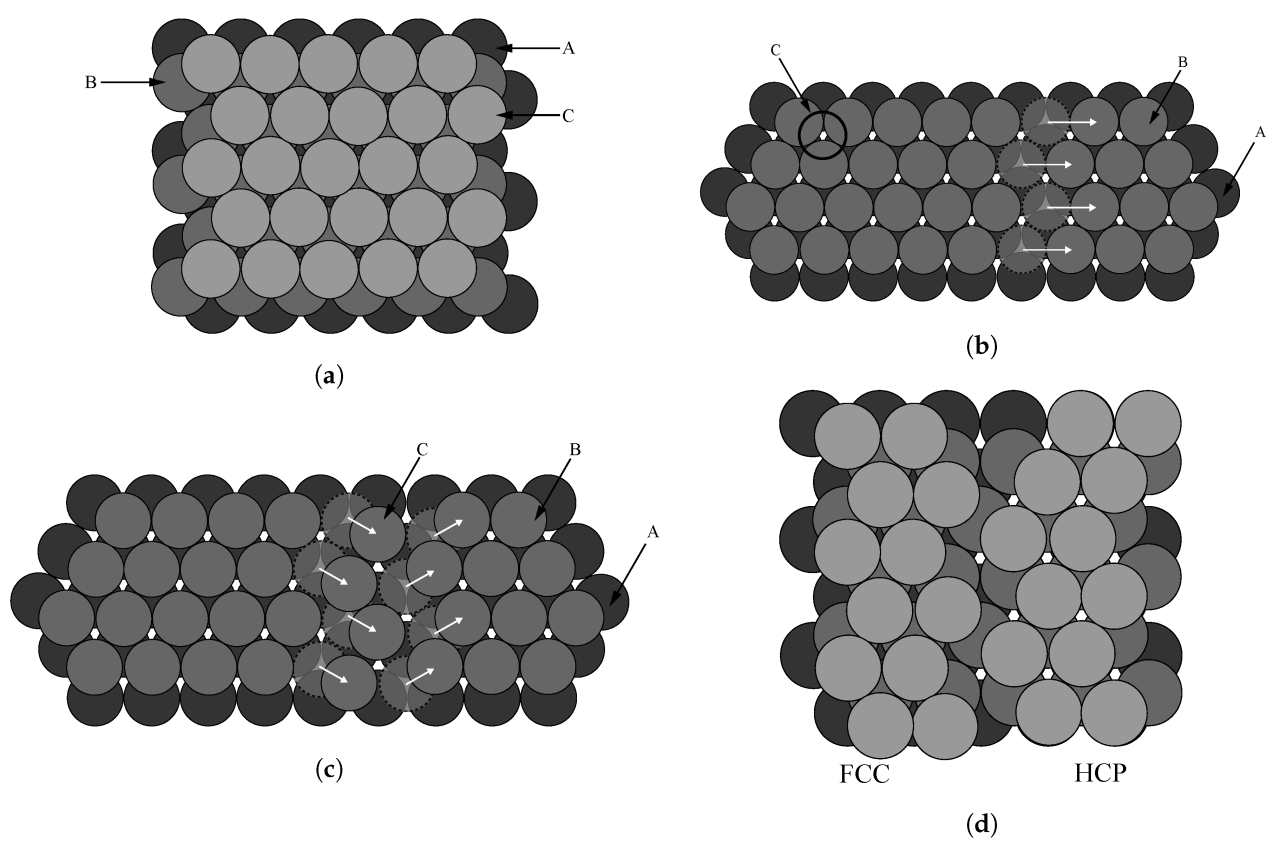

The crystal structure of Cu-Zn alloy is face-centered cubic (FCC), similar to pure copper. In this structure, the atoms are arranged in a cubic lattice with each atom surrounded by 12 equidistant neighbors. The bonding in Cu-Zn alloy is primarily metallic, involving the sharing of free electrons between the copper and zinc atoms.

Atomic Composition

The atomic composition of Cu-Zn alloy can vary widely, with the proportion of copper ranging from 50% to 95% and the proportion of zinc ranging from 5% to 50%. The composition of the alloy affects its properties, such as strength, hardness, and corrosion resistance.

Crystal Structure

The crystal structure of Cu-Zn alloy is face-centered cubic (FCC), similar to pure copper. In this structure, the atoms are arranged in a cubic lattice with each atom surrounded by 12 equidistant neighbors. The FCC structure is a common crystal structure for metals and is responsible for many of the properties of metals, such as their strength and ductility.

Bonding Characteristics

The bonding in Cu-Zn alloy is primarily metallic, involving the sharing of free electrons between the copper and zinc atoms. Metallic bonding is a strong type of bonding that results in a strong and cohesive material. The strength of the metallic bond is due to the attraction between the positively charged metal ions and the negatively charged free electrons.

Electrical and Thermal Conductivity

Electrical conductivity is a crucial factor in distinguishing between metals and nonmetals. Metals possess high electrical conductivity due to the presence of mobile electrons that can freely move throughout the material. This allows metals to conduct electricity efficiently. In contrast, nonmetals have low electrical conductivity because they lack these mobile electrons.The

electrical conductivity of Cu-Zn alloy falls within the range of typical values for metals. This indicates that Cu-Zn alloy exhibits metallic properties in terms of electrical conductivity.Thermal conductivity is another important property that can provide insights into the classification of materials.

Metals generally have high thermal conductivity, meaning they can transfer heat efficiently. This is because the mobile electrons in metals can also carry heat energy. Nonmetals, on the other hand, have low thermal conductivity due to the absence of these mobile electrons.The

thermal conductivity of Cu-Zn alloy is also within the range of typical values for metals. This further supports the classification of Cu-Zn alloy as a metal.

Electrical Conductivity of Cu-Zn Alloy

The electrical conductivity of Cu-Zn alloy varies depending on the composition and microstructure of the alloy. Generally, the electrical conductivity of Cu-Zn alloy decreases with increasing zinc content. This is because zinc atoms have a lower electrical conductivity than copper atoms.

Thermal Conductivity of Cu-Zn Alloy

The thermal conductivity of Cu-Zn alloy is also affected by its composition and microstructure. The thermal conductivity of Cu-Zn alloy generally decreases with increasing zinc content. This is because zinc atoms have a lower thermal conductivity than copper atoms.

Luster and Reflectivity

Luster, the ability of a surface to reflect light, can distinguish between metals and nonmetals. Metals possess a characteristic metallic luster due to their tightly packed, regularly arranged atoms. This arrangement allows for the free movement of electrons, enabling the reflection of light waves and giving metals their shiny appearance.

Luster of Cu-Zn Alloy

Cu-Zn alloy, commonly known as brass, exhibits a metallic luster. The alloy’s composition and microstructure contribute to this property. Brass contains a high proportion of copper, which is a metal known for its luster. Additionally, the alloy’s crystalline structure allows for the orderly reflection of light waves, enhancing its luster.

In comparison to pure copper, brass exhibits a slightly reduced luster due to the presence of zinc. Zinc, a nonmetal, does not possess the same high electron mobility as copper. However, the alloy’s overall metallic character and the dominant presence of copper result in a metallic luster that is comparable to other metals.

Malleability and Brittleness

Malleability and brittleness are two contrasting properties that can help distinguish between metals and nonmetals. Malleability refers to a material’s ability to be hammered or rolled into thin sheets, while brittleness indicates a material’s tendency to break or shatter when subjected to stress.

Metals are generally malleable, meaning they can be deformed without breaking. This is due to their strong metallic bonds and the ability of their atoms to slide past each other. In contrast, nonmetals are typically brittle and break easily under stress.

Their bonds are often weaker, and their atoms are more tightly bound in specific arrangements, making them less able to deform.

Malleability and Brittleness of Cu-Zn Alloy

The malleability and brittleness of Cu-Zn alloy depend on its composition and microstructure. Pure copper is highly malleable, but the addition of zinc can make the alloy more brittle. This is because zinc atoms disrupt the regular arrangement of copper atoms, creating defects and grain boundaries that can weaken the material.

The composition of the alloy also affects its malleability. Alloys with a higher zinc content are more brittle than those with a lower zinc content. Additionally, the microstructure of the alloy can influence its malleability. Alloys with a fine-grained structure are generally more malleable than those with a coarse-grained structure.

In general, Cu-Zn alloys are less malleable than pure copper but more malleable than many nonmetals. Their brittleness can vary depending on the alloy’s composition and microstructure.

Chemical Reactivity

Chemical reactivity is a crucial aspect in understanding the nature of materials. Metals and nonmetals exhibit distinct chemical behaviors, and examining the reactivity of Cu-Zn alloy can shed light on its classification.

Cu-Zn alloy exhibits moderate chemical reactivity, unlike highly reactive metals such as sodium or potassium. It reacts with acids like hydrochloric acid (HCl) to produce hydrogen gas (H2) and the corresponding metal salts. However, it does not react with water at room temperature.

Reactivity towards Oxygen

Cu-Zn alloy is susceptible to oxidation, forming a protective layer of copper and zinc oxides on its surface when exposed to air or oxygen. This oxide layer prevents further oxidation and enhances the alloy’s corrosion resistance.

Reactivity towards Acids, Is cu-zn alloy a metal or nonmetal

Cu-Zn alloy reacts with acids, releasing hydrogen gas and forming metal salts. The rate of reaction depends on the concentration and temperature of the acid. Stronger acids and higher temperatures accelerate the reaction.

Conclusion

Based on the analysis conducted, we can conclude that Cu-Zn alloy exhibits characteristics that align with those of metals rather than nonmetals. Its classification as a metal has significant implications for its potential applications.

The metallic nature of Cu-Zn alloy suggests that it possesses properties such as high electrical and thermal conductivity, luster, malleability, and brittleness. These properties make it suitable for use in various applications, including electrical wiring, heat exchangers, and decorative items.

Implications for Applications

The classification of Cu-Zn alloy as a metal opens up a wide range of potential applications due to its unique combination of properties.

- Electrical Conductivity:Its high electrical conductivity makes it an excellent choice for electrical wiring, ensuring efficient transmission of electricity.

- Thermal Conductivity:The alloy’s high thermal conductivity enables it to effectively transfer heat, making it suitable for use in heat exchangers and cooling systems.

- Malleability:The malleability of Cu-Zn alloy allows it to be easily shaped and formed into various components, enhancing its versatility for different applications.

FAQ Explained

What is the composition of Cu-Zn alloy?

Cu-Zn alloy, also known as brass, is composed of varying proportions of copper (Cu) and zinc (Zn). The specific composition determines the alloy’s properties and applications.

How does electrical conductivity differentiate between metals and nonmetals?

Metals possess high electrical conductivity due to the presence of mobile electrons, while nonmetals are poor conductors. Cu-Zn alloy’s high electrical conductivity indicates its metallic nature.

What is the significance of malleability in classifying Cu-Zn alloy?

Malleability, the ability to be hammered or rolled into thin sheets, is a characteristic of metals. Cu-Zn alloy’s malleability further supports its classification as a metal.