How can you check slack adjusters cdl? This comprehensive guide provides a detailed overview of slack adjusters, their importance in commercial driving, and effective methods for checking and maintaining them. By understanding the role and proper maintenance of slack adjusters, CDL drivers can ensure vehicle safety and compliance with industry regulations.

Slack adjusters play a crucial role in maintaining optimal brake performance, ensuring vehicle stability and preventing premature wear. This guide covers manual and diagnostic techniques for checking slack adjusters, troubleshooting common issues, and best practices for their management. By adhering to the recommended maintenance schedule and industry standards, CDL drivers can maximize the lifespan and effectiveness of slack adjusters, contributing to overall road safety.

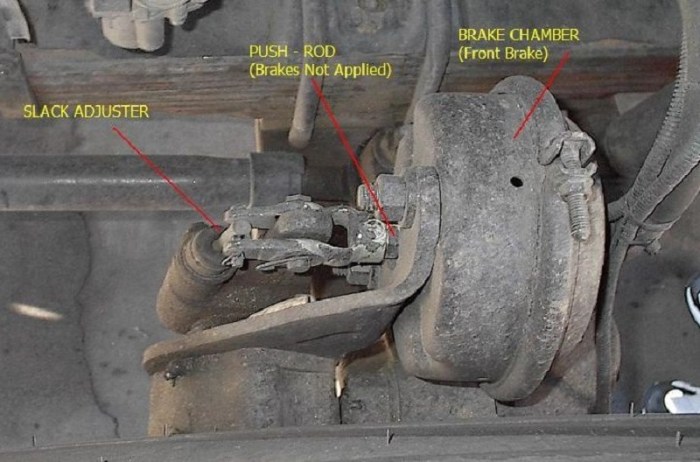

Overview of Slack Adjusters

Slack adjusters play a crucial role in the commercial driving industry by ensuring the proper functioning of brake systems in commercial vehicles. These devices automatically adjust the slack between the brake shoes and drums or pads and rotors, maintaining optimal braking performance and ensuring compliance with safety regulations.

Maintaining properly adjusted slack adjusters is essential for vehicle safety and compliance. Neglecting slack adjuster maintenance can lead to reduced braking effectiveness, premature brake component wear, and potential safety hazards.

Methods to Check Slack Adjusters

Manual Inspection

- Park the vehicle on a level surface and engage the parking brake.

- Use a slack adjuster tool to measure the slack between the brake shoes and drums or pads and rotors.

- Compare the measured slack to the manufacturer’s specifications.

Diagnostic Tools

- Connect a brake tester to the vehicle to measure brake system performance, including slack adjuster effectiveness.

- Analyze the brake tester results to identify any issues with slack adjuster performance.

Troubleshooting Common Issues, How can you check slack adjusters cdl

- Wear:Over time, slack adjusters can wear out, reducing their ability to maintain proper brake adjustment.

- Corrosion:Exposure to moisture and road salt can cause slack adjusters to corrode, hindering their movement.

- Improper Adjustment:Incorrect adjustment of slack adjusters can lead to excessive or insufficient slack, compromising braking performance.

Troubleshooting Tips

- Replace worn or damaged slack adjusters.

- Clean and lubricate corroded slack adjusters to restore their functionality.

- Re-adjust slack adjusters to manufacturer’s specifications.

Maintenance and Inspection

Slack adjusters require regular maintenance and inspection to ensure optimal performance and prevent potential issues. The recommended maintenance schedule varies depending on the vehicle type and operating conditions.

Regular inspections should include a visual check for wear, corrosion, or damage, as well as a manual or diagnostic measurement of slack to ensure it meets specifications.

Regulations and Compliance

Industry regulations and standards mandate the proper maintenance and adjustment of slack adjusters. Non-compliance can result in fines, vehicle impoundment, and potential safety violations.

Adhering to safety guidelines and following recommended maintenance schedules is crucial for ensuring the safety and compliance of commercial vehicles.

Best Practices for Slack Adjuster Management

- Use proper adjustment techniques to ensure optimal slack adjuster performance.

- Keep accurate records of slack adjuster maintenance and inspections.

- Provide training to drivers and maintenance personnel on the importance and proper management of slack adjusters.

By following these best practices, fleet operators can optimize slack adjuster performance, extend their lifespan, and ensure the safety and compliance of their vehicles.

Question Bank: How Can You Check Slack Adjusters Cdl

What are the signs of worn or malfunctioning slack adjusters?

Excessive brake pedal travel, uneven brake wear, and reduced braking effectiveness can indicate worn or malfunctioning slack adjusters.

How often should slack adjusters be checked?

Slack adjusters should be checked regularly as part of a comprehensive brake inspection, typically every 6 months or 12,000 miles.

What are the consequences of non-compliance with slack adjuster regulations?

Non-compliance with slack adjuster regulations can result in fines, vehicle impoundment, and potential legal liability in the event of an accident.